In part six of our 12-week development programme, the IAA – and its category partner JTI – help forecourt retailer Toby Stokes improve his availability

In the sixth week of our guide to improving your business with the IAA, our focus shifts to availability. Maintaining availability means monitoring sales and stock to ensure you can always meet customer demand and expectations, ensuring shoppers can buy what they need and therefore remain loyal to your store.

Before we look at this week’s benchmarks, find out how Mark Yexley, head of communications at category partner JTI assisted Toby Stokes to come up with an action plan to improve the store’s processes in order to avoid shelf gaps based on the IAA benchmarks.

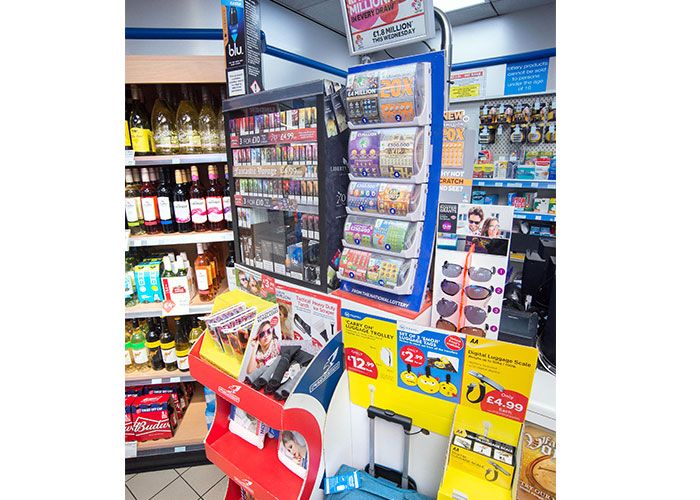

Toby’s shop is a forecourt and is part of a group of three shops around Thetford. It is on a busy A-road so has a lot of passing trade, yet has very small storage which makes him even more vulnerable to availability problems. How can the IAA help Toby improve his availability and keep his customers coming back for more?

Why I take part

Availability is not really something we have planned for in the past. It is important and we have considered what we should do but it’s not been our primary focus. If we run out of something, a customer might not return.

With this visit from the IAA and JTI, I feel we have something concrete we can act on.

The checklist system suggested is definitely something we want to implement as soon as possible.

IAA Advice for Toby

Toby’s challenge: Setting targets and monitoring success

Toby uses his EPoS system to auto-order items when they get low but does not record when something has sold out, meaning some items are out of stock for long periods. What can he do to avoid these availability gaps?

Mark says: “Think about setting a target. Although many stores aim for higher, 95% is a good goal to begin with. That means you would, at most, have one product out of 20 unavailable at any one time. By having a target and having a 10-minute team meeting each morning to discuss availability, you’ll show your team the importance of spotting gaps and find they are solved faster.”

Action: Set an availability target and organise 10-minute team meetings each morning to discuss and solve gaps.

Toby’s challenge: Managing suppliers and deliveries to maintain availability

Toby sometimes finds deliveries are missing items. If this happens he will speak to his local rep, go to a nearby wholesaler or borrow stock from another store, but it always falls to him to action. How can his team help?

Mark says: “Knowing what you need to do if an issue arises is a great start. Calling your rep can be a quick fix, if they are in the area then they can pop in, but this won’t always be possible. By formalising your steps into a written plan, talking through it with your team and displaying it in the office, they’ll know what to do, meaning you can react quicker.”

Action: Create a written plan for when you have stock issues and share it with your team so they can be solved quicker.

Toby’s challenge: Managing day-to-day tasks and checks

The shop has three main busy periods, early morning, lunchtime and early evening. Due to the limited space, displays can get messy and gaps appear over the course of the day. What can Toby do to avoid this happening?

Mark says: “You get good footfall, especially during peak times, but that can have its own challenges. Customers may forgive you for some missing items, but for items such as tobacco, many will buy elsewhere if their chosen brand is unavailable, often taking their entire spend with them. Introduce gap checks after each busy period – this will enable you to solve problems before the next one.”

Action: Introduce gap checks after busy periods so you can spot and deal with availability issues before the next busy period.

Partner advice

Mark Yexley, head of communications, JTI

“Maintaining availability is essential for stores like Toby’s. He has got some solid plans already in place and by formalising them, introducing a few checks and involving the team more, he will be able to secure customer loyalty and drive spend.”

Comments

This article doesn't have any comments yet, be the first!